My goal as an engineer is to glorify God through benevolent, quality engineering.

This site is a bit of a time machine, so enjoy! The best way to contact me is at jabbott@mit.edu.

Engineering Projects

World's First Launched AI Power Tool

Launched 2022 I engineered Milwaukee Tool's Gen IV drill kickback AI algorithm.

This kickback control does AI inference at the edge to help detect bind-up.

It's loved by our users now with over 100k drills sold.

This kickback control does AI inference at the edge to help detect bind-up.

It's loved by our users now with over 100k drills sold.

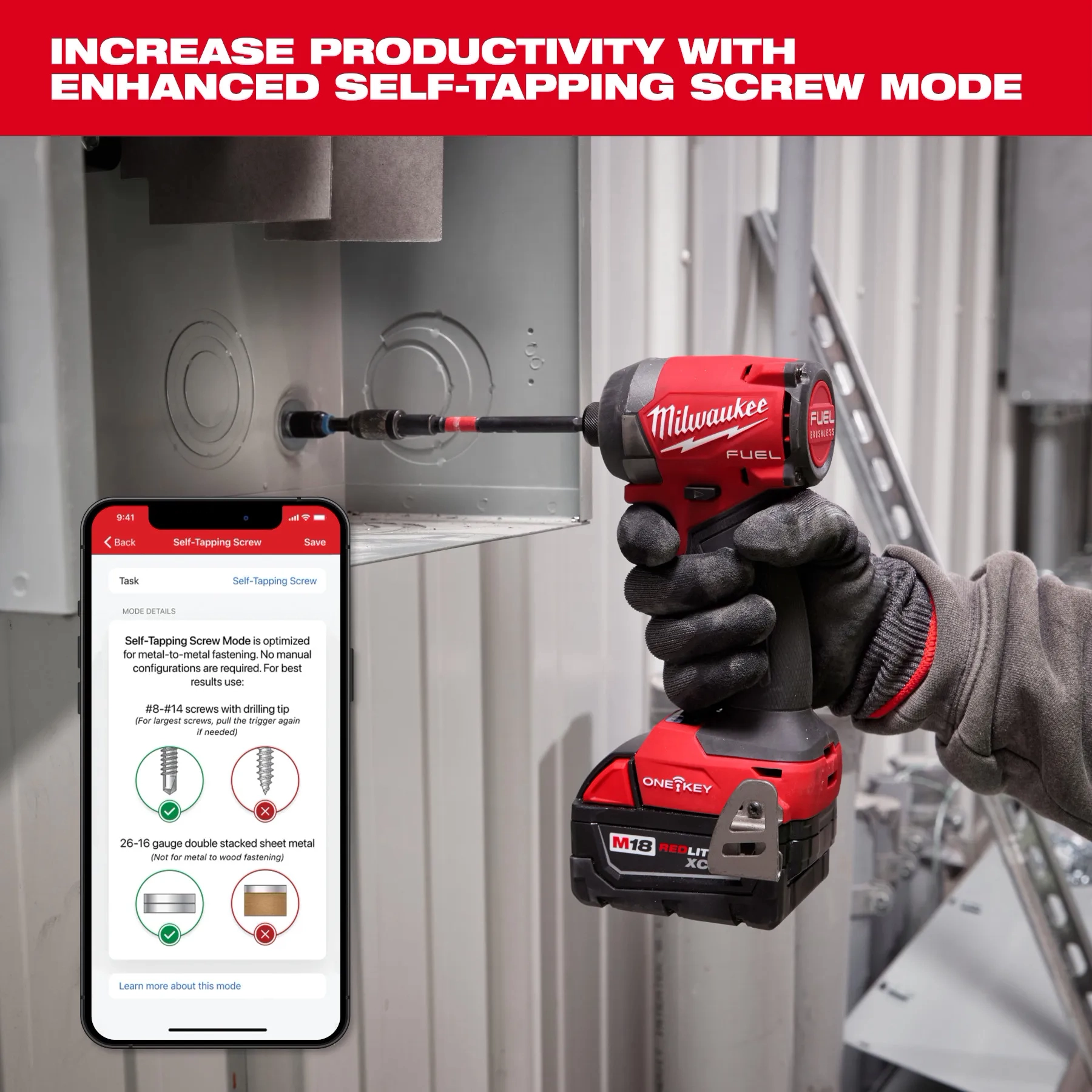

AI Screw Seating Impact Driver

Launched 2023 I engineered an AI Tek Screw Mode for our premium IoT impact driver.

The AI helps screw seating across a wide range of screw sizes and sheet metal gauges.

This is the world's first AI screw seating tool.

The AI helps screw seating across a wide range of screw sizes and sheet metal gauges.

This is the world's first AI screw seating tool.

Machine Learning at Milwaukee Tool

2016 - 2023 I was introduced to AI right before graduating from MIT.

So when I joined the Front End Innovation team, I kickstarted and grew the AI team.

There were dozens of PoCs for predictive maintenance, vision, and realtime controls.

Publically visible are many of the AI filings.

So when I joined the Front End Innovation team, I kickstarted and grew the AI team.

There were dozens of PoCs for predictive maintenance, vision, and realtime controls.

Publically visible are many of the AI filings.

Mechanical Engineering Innovation at Milwaukee Tool

2016 - 2023 Mechatronic innovation is my favorite!

I love deep technical dives, user-centered design, and all forms of innovation.

I love deep technical dives, user-centered design, and all forms of innovation.

Check out all 40+ filed patents (25 granted) here.

Improving Indian Beehives and Beekeeping

Summer 2014 - January 2016 Sponsored as an MIT Tata Fellow, I used mechanical engineering to improve Indian beehives. The work delved into fluid dynamics, manufacturing, and mechanics, and I focused on the low-hanging fruit / highest impact items for Indian beekeepers.

- Thesis Improving Indian Beehives and Beekeeping

- YouTube Series

- Presentation for Indian Bee Trainers

- Thesis Improving Indian Beehives and Beekeeping

- YouTube Series

- Presentation for Indian Bee Trainers

Loop Control: Laser Light Show

Fall 2014 For a graduate mechatronics course, I stabilized two galvanometers from a prebuilt rig. I used feedforward lead-lag control to direct the laser to draw geometric shapes with minimal overshoot using Labview.

Backdrivable Robots

Spring 2014 I spent one semester with the Hover Research Group researching backdrivable robots using the Baxter with the goal of underwater use.

Intro to Architecture

January 2014 To graduate from MIT a semester early, I took a studio based arts class that explored designing across scales with nature as inspiration. See my portfolio page.

Engineering Balance Conceptually

Fall 2013 I wrote my senior thesis on how to engineer systems requiring balance, especially with humans. Human balance is unpractical to clasically model, and so I derived a conceptual framework that isolates three mechanisms used to control one's motion. Read the thesis.

2.009 Product Engineering Process (Senior Capstone)

Fall 2013 The team of 19 made a navigational heads-up display for motorcyclists. I led 1) external and internal development of the Android app and 2) user input. Placed first out of eight teams. See the team brochure.

Verilog Brick Breaker Game

Voice Controlled Poker Game

Fall 2013 Our team of four crafted a working voice-controlled poker game proof-of-concept. I coded a round of betting logic in php interfacing to an external call recognition service. Included was a custom HDTV poker table to feature our original realtime rendering and a 52-page report. We had gone all-in for quad aces.

Automated Test Stand

Summer 2013 At Vecna in Cambridge, MA, I designed and coded an internal application to test and calibrate hydraulic robots. The Python and Tkinter application improves the efficiency and safety of Vecna's engineers and technicians with real-time graphs of sensor readings, integrated calibration and data collection reports, and extensibility for endurance testing. Watch the video.

Study Abroad at Cambridge University

Spring 2013 During studying abroad at Cambridge University in England, I completed two team projects: a bicycle design project and a CAD/CAM project. The bicycle design project used fatigue analysis to determine the lifetime of bicycle handlebars and the CAD/CAM project introduced me to Creo, Abaqus FEM, and PowerMILL. (At MIT I have used SolidWorks and MasterCAM.)

2.008 Design and Manufacturing Yo-yo Project

Fall 2012 My team of eight designed an impressive yo-yo for which we created the molds and then injection molded / thermoformed. The center white gear spins freely.

2.671 Go Forth and Measure: Improving the Shape of a Jump Rope

Haptic Research at CINVESTAV's Mechatronics Group in Mexico City

Summer 2012 My Mexican partner and I compared two haptic (or touch) teleoperation interfaces. I designed the experiment, coding our Android remote control application with vibrational feedback to compare to his master robotic arm with force feedback. Concluded with a 30-minute oral presentation in Spanish.

2.007 Design and Manufactoring I

Spring 2012 I designed and manufactored a scissor lift robot to lift a slug. The robot fared alright and I gained experience with all the tools in the shop.

AirVentions Internship

January 2012 I worked at AirVentions Inc., a startup in Boston that makes collision avoidance systems. I worked in SolidWorks and helped to design the enclosure for the sensors. In a 12-page internal report, I presented four SolidWorks models for the enclosures, detailed the manufactoring and marketing benefits of my most recommended design, and outlined design requirements for future engineers.

Autonomous Line-following Robot

Fall 2011 With my partner Daniel Gonzalez, we won first in our 2.S994 Electronics for Engineers class of 30 MIT students for fastest time.

Please check out my educator page or enthusiast page for many more projects. Or learn a little more about how I fit on your team.

Privacy Matters | Copyrighted